Services

The smart alternative

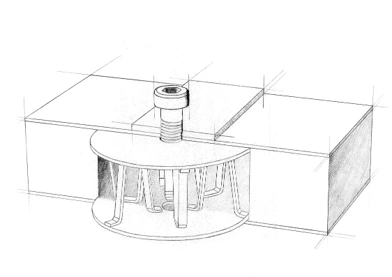

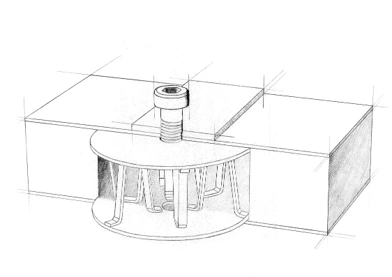

Bionic Lite - Inlay

The production of assembly zones, e.g. a screw connection in sandwich materials, often requires a local substitution of the lightweight core material with heavy, solid inserts.

The Bionic Lite insert from Fox Core fulfills this task with a significantly lower mass input than is necessary with solid inserts - and with the same strength of the connection!

Your advantages over solid inserts:

Product features:

Bionic Lite insert in comparison

| State of the art | Fox Core | |

|---|---|---|

| Insert – design | Aluminum - massive | Aluminum - bionic |

| Insert – dimensions in mm | 100 x 100 x 10 | 100 x 100 x 10 |

| Load capacity | ca. 9.000 N | ca. 10.000 N |

| Insert mass | 260 g | 120 g |

| Costs (ready to install) | moderate | moderate |

In cooperation with:

Robust and lightweight at the same time

ZelMet – Sandwich Panel

The ZelMet metal panels from Fox Core are the result of the consistent application of our lightweight construction concept together with our customers.

The structural elements that form the core of the panel can be arranged to suit the load, ensuring a core structure with minimum mass for the intended use.